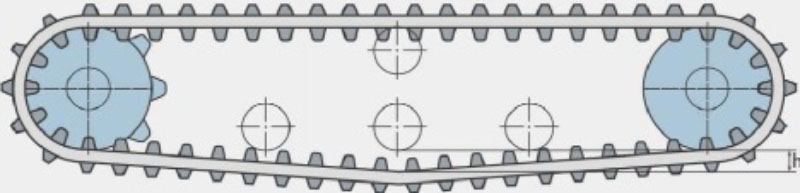

The appropriate tension should be adjusted during the installation of rubber tracks. The specific method is to lift the machine off the ground, let the rubber track naturally sag, and measure the distance h between the middle support wheel and the rubber track, as shown in the following figure. Adjust the tension wheel to ensure that the h value is within the standard range, as shown in the table below.

| Rubber track width W | h value standard |

| 120<W≤250 | 10~20mm |

| 250<W≤350 | 20~25mm |

| 350<W≤450 | 25~30mm |

| 450<W≤550 | 30~35mm |

When the tension is insufficient, it is easy to cause derailment, and the teeth of the guide wheel and support wheel may be stuck, which can easily cause the rubber track to suddenly generate huge tension and break. When the tension is excessive, the track pitch will become longer under the long-term action of high tension, causing abnormal wear on the core metal and driving wheels.

Previous post:There is no more.